PRODUCT CATEGORIES

Performance characteristics

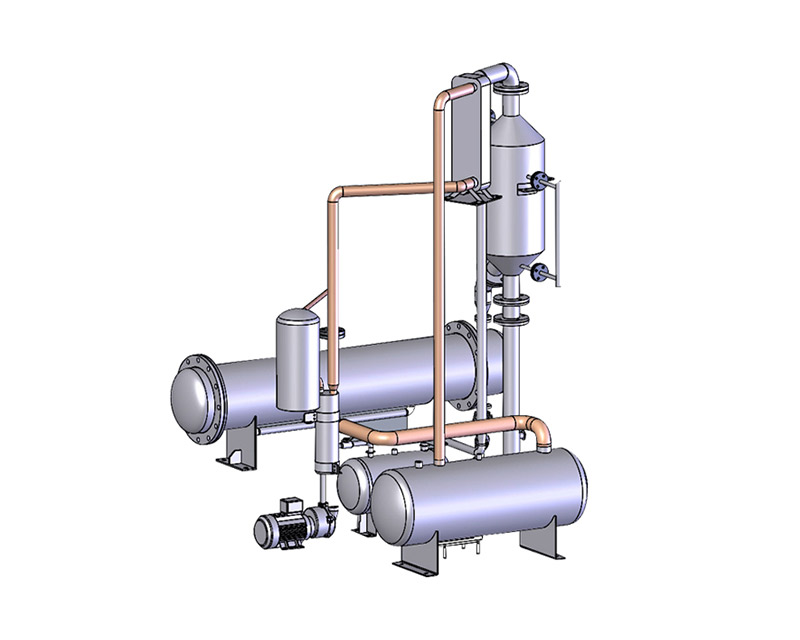

multi effect falling film evaporator has been our company's finalized product. According to the evaporation capacity, it can be classified as 1000-20000kg / h (Series).

the evaporation temperature is low. If the secondary steam is used for heating, the heat will be fully utilized, and the evaporation temperature is relatively low. With large concentration ratio and falling film evaporation, it is suitable for materials with low viscosity or high viscosity and good solubility. The feed liquid is easy to flow and evaporate, not easy to scale, and the concentration time is short. The concentration ratio can reach 1:5.

falling film evaporator can be designed into different process flow according to the characteristics of different materials, and can also be equipped with automatic control system according to the requirements of different users.

technical parameter

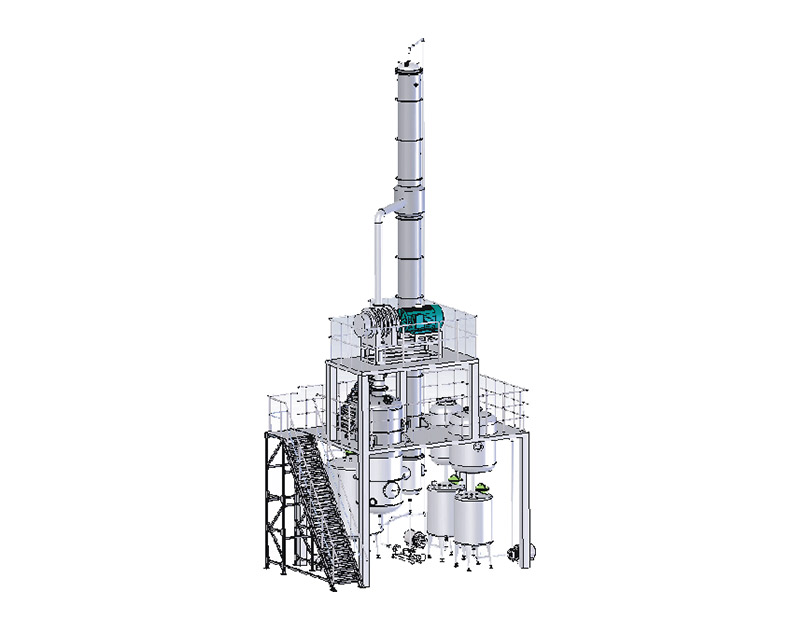

It can realize full-automatic control and self-learning full-automatic control of key control points such as sugar content;

In the evaporation process, one-time discharge can be realized without circulation;

The temperature of the first effect evaporation is low, and the retention time of juice in the evaporator is short (no more than 3min), which can greatly maintain the original color, fragrance, taste and composition of the processed materials;

LOCATION :

LOCATION :

Order Now

Order Now Collection

Collection